Have any Questions?

Feel free to Get in touch

Heavy Duty Omnidirectional AGV

This vehicle features a completely flat surface design for enhanced compatibility. The initial design intention is to seamlessly integrate with heavy-duty storage racks, ensuring smoother movement and minimizing the chances of tilting to zero during transportation.

Feel free to Get in touch

product details:

Automatic Guided Vehicle

Automatic guided vehicle systems, also known as an AGV system, otherwise known as an automated guided vehicle, autonomous guided vehicles, or even automatic guided cart, is a system that follows a predestined path around a facility. An AGV automated guided vehicle is a motorized vehicle that carries a load through either an assembly, manufacturing, or warehousing facility. An AGV can take on any form a customer requires to best address their application needs.

Advantages of AGV:

1.Efficiency improvement: 24-hour continuous operation, reduced dependence on manual labor, and shortened production cycle.

2.Safety: Avoid manual operation errors and reduce the risk of work-related injuries.

3.Flexibility and scalability: Quickly adjust paths and tasks to adapt to changes in production lines.

4.Cost optimization: Reduce manpower, equipment maintenance and site occupation costs.

5.Data-driven: Real-time monitoring of transportation status and optimization of production processes.

| Product Name | Heavy duty omni direction AGVs |

| Model Number | LY-AU-40T-4-0A |

| Product Weight | 15T |

| Load Weight | 40T |

| Product Size | L5500*W2650*H730 |

| Drive Unit Type | Superdrive |

| Drive Unit Number | 4-Drive |

| Drive Unit Load Weight | 15T |

| Remote Control | Manual Remote |

| Navigation Type | Magnetic Stripe |

| Lift Ability | Yes/Overall |

| Castor | 0 |

| Linkage Mode | Single AGV |

| Frame Structure | Tubesheet |

| Suspension Type | Hydraulic |

| Turning Radius | Rotate on spot |

| Voltage | 96V |

| Range/Battery | 450AH |

| Fixture/Tooling | / |

| Explosion-proof level | – |

| Explosion-proof or not | No |

| Safety Features | Collision Avoidance System, Emergency Stop Button, Obstacle Detection Sensors, Safety Laser Scanner |

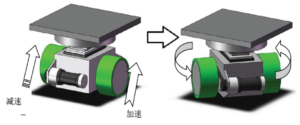

No matter 8-drives FLAT MOVER, or 20-drive FLAT MOVER, the whiles are controlled by IPC precisely, each wheel is in the right Angle in each mode of movement.

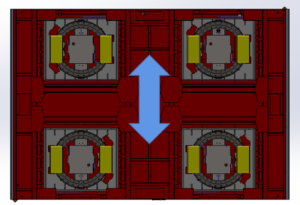

Go straight

All assemblies are consistent with the length direction of the vehicle body and move together (see the figure to go straight).

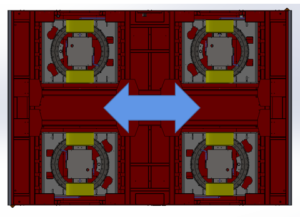

Lateral move

All assemblies are consistent with the width direction of the vehicle body and move together (see the translation in the figure).

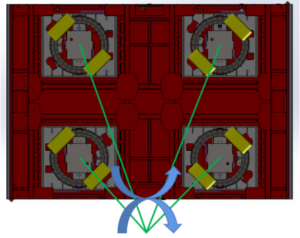

Turn

The inboard drive assembly in the direction of movement is the master drive unit, and the other assemblies are slave control drive assemblies (see the figure for turning) that move together.

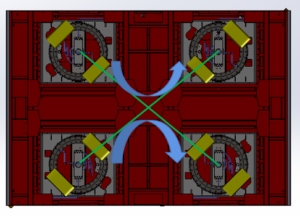

Rotate on spot

Steering with the geometric center of the vehicle (see turning in the figure), it rotates on the spot, and all assemblies are perpendicular to the geometric center and move together.

Omni-directional movement is the goal of our drive unit design.

multiple sets of differential drive wheels, which can not only actively carry load, but also actively drive steering, so as to realize omni-directional movement forms such as straight running, horizontal turning, turning and zero turning radius in two-dimensional plane. Under the condition that the height and size of the chassis of the car body are fixed, several sets of heavy-duty differential wheels are selected as the driving and walking carriers of the car body, and the main load is borne by the driven bearing wheel. When used, one drive device and two bearing casters are installed on each side of the AGV chassis, and the AGV drive device is symmetrically set on the central axis of the length direction of the vehicle body to ensure stable support.

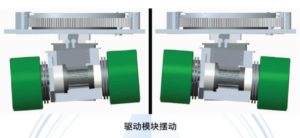

The whole mechanism integrates the wheel, drive motor, reducer and steering mechanism structurally, with small space size and convenient interface installation. It can meet the functional layout of the walking mechanism in a small space.

1) The drive unit is a multi-wheel multi-drive structure driven by 1 driver and 1 differential drive;

2) One drive unit contains, encoder, reducer, servo motor, etc.

4) Durable design makes differential drive bear rough conditions.

High load capacity 5-ton unit, 10-ton unit, 15-ton unit, 30-ton unit, 60-ton unit. Patented hydraulic/spring suspension design.

Wide ground adaptability, runs inside and outside the plant.

Automotive Industry: Transporting car bodies, engines, large molds, etc., supporting flexible production lines.

Heavy Machinery Manufacturing: Transporting large castings, welded parts or assembly components.

Metallurgical Industry: Transporting steel coils, steel plates, and high-temperature metal materials.

Chemical industry: transporting reactors, large storage tanks or hazardous chemicals.

Ports/airports: automated loading and unloading and stacking of containers and large goods.

Large warehouses: storage and sorting of palletized heavy goods.

Railway freight: cooperate with gantry cranes to carry out cargo handling in carriages.

High-temperature workshops: such as transporting high-temperature steel billets in steel plants.

Explosion-proof scenarios: transportation of flammable and explosive materials in the oil and gas industry.

Clean environment: heavy wafer handling in clean rooms in semiconductor factories.

Wind power industry: in-plant transportation of super-large components such as blades and towers.

Battery production: handling heavy battery modules or energy storage equipment.

Infrastructure engineering: automated transportation of prefabricated components and building materials.

Linked with robots and CNC machine tools to achieve precise cross-station delivery of heavy-loaded workpieces and support the construction of “dark factories”.

At sem a enim eu vulputate nullam convallis Iaculis vitae odio faucibus adipiscing urna.

sales@lonyurobot.com

+86 136 8205 1821

No. 2-3, Wei 7th Road, Microelectronics Industrial Park, Xiqing District, Tianjin, China

Copyright © 2025 Lonyurobot.com